In the critical domain of hazmat handling, traditional training methods often fall short. To address this gap, the Emergency Transfer Training Simulator for Hazmat introduces the Valve Leak Training Unit (VLTU), offering a safe, controlled environment to simulate diverse leak scenarios from minor to severe. This advanced training significantly enhances safety protocols, expedites response times, and ultimately saves lives by:

– Replicating various industrial valves and dynamic hazardous substance behavior.

– Incorporating integrated safety mechanisms for comprehensive emergency preparedness.

– Enabling realistic practice with authentic hardware in immersive scenarios.

– Enhancing understanding of emergency procedures and preparing personnel for effective response in actual hazmat incidents.

In today’s world, effective emergency response to hazardous material (Hazmat) incidents is paramount. Traditional training methods often fall short in replicating real-world complexities. This introduces a critical gap in preparedness. To bridge this, innovative solutions like the valve leak training unit emerge as powerful tools. This article explores the emergency transfer training simulator for Hazmat, delving into its key features, benefits, and real-world applications, while also glancing at future trends in Hazmat training.

- Understanding the Need for Emergency Transfer Training

- Key Features of a Valve Leak Training Unit

- Simulation Technology in Hazmat Training

- Benefits of Using a Digital Training Simulator

- Real-World Applications and Use Cases

- Future Trends in Hazardous Material Training

Understanding the Need for Emergency Transfer Training

In the high-pressure environment of hazardous material (hazmat) handling, every second counts in an emergency. Traditional training methods often fall short when it comes to replicating the intensity and unpredictability of real-world scenarios. This is where an Emergency Transfer Training Simulator for Hazmat steps in as a revolutionary tool. The need for such advanced training is evident, especially considering the potential consequences of a valve leak or other critical incidents involving hazardous substances.

A Valve Leak Training Unit (VLTU) offers a realistic and controlled environment to prepare responders for various emergencies. By simulating different leak scenarios, from minor leaks to full-scale disasters, this technology ensures that personnel gain invaluable hands-on experience without putting themselves or others at risk. This innovative approach to training enhances safety protocols, improves response times, and ultimately saves lives in the event of a hazardous material incident.

Key Features of a Valve Leak Training Unit

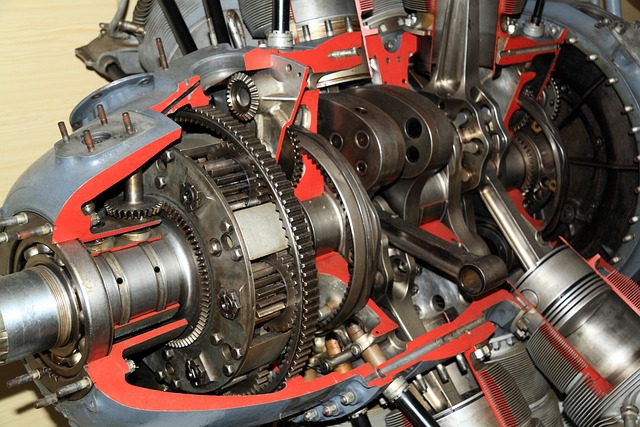

A Valve Leak Training Unit is an indispensable tool for preparing emergency responders to handle hazardous material (hazmat) incidents involving valve leaks. Key features distinguish these units from standard training equipment, ensuring a realistic and effective learning experience. First, they replicate the physical attributes of various valves commonly found in industrial settings, allowing trainees to practice leak containment techniques on authentic hardware. This realism is crucial for building confidence and muscle memory in response scenarios.

Additionally, advanced valve leak training units incorporate dynamic simulation capabilities, mimicking the unpredictable behavior of hazardous substances. Trainees can experience the challenges of containing leaks from different types of valves under varying pressure levels and flow rates. These features enable first responders to develop versatile skills applicable across diverse hazmat situations. Such units also often include integrated safety mechanisms to safeguard trainees from potential risks associated with handling harmful materials, making them ideal for comprehensive emergency preparedness training.

Simulation Technology in Hazmat Training

In the realm of hazardous materials (Hazmat) management, Simulation Technology has emerged as a game-changer, revolutionizing training methods and enhancing safety protocols. One innovative tool that exemplifies this is the Emergency Transfer Training Simulator, specifically designed for valve leak training units. This cutting-edge simulation provides a controlled environment to train personnel on responding to critical situations involving hazardous substances.

By replicating real-world scenarios, the simulator allows trainees to experience various challenges without endangering themselves or the surrounding environment. Trainees can practice skills such as quickly identifying and mitigating valve leaks, donning personal protective equipment (PPE), and safely transferring hazardous materials from one container to another. This immersive training fosters a deeper understanding of emergency procedures, ultimately preparing them for effective response in real-world Hazmat incidents.

Benefits of Using a Digital Training Simulator

In today’s digital era, adopting innovative training methods is essential for preparing emergency responders to handle hazardous material (hazmat) incidents effectively. One such game-changer is the emergency transfer training simulator, which offers numerous advantages over traditional in-person training. By replicating real-world scenarios, this cutting-edge technology allows trainees to gain hands-on experience in a controlled environment, minimizing risks associated with live exercises involving hazardous substances.

The use of a digital simulator, such as a valve leak training unit, enables consistent and repeatable practice sessions. Trainees can perfect their skills in isolating and containing leaks without the worry of exposure to toxic materials. This sophisticated tool facilitates personalized learning, allowing each trainee to focus on specific areas of improvement. Moreover, it provides immediate feedback, ensuring individuals grasp critical procedures and gain confidence in their abilities before encountering actual hazmat situations.

Real-World Applications and Use Cases

In real-world scenarios, emergency response teams often face challenging situations involving hazardous materials (Hazmat). Training for such events is crucial to ensure personnel are prepared and equipped to handle critical incidents effectively. The Valve Leak Training Unit serves as a cutting-edge tool in this context, offering immersive and realistic practice environments. This simulator enables first responders to train for various Hazmat scenarios, including valve leak situations, without putting themselves or the public at risk.

By simulating real-life conditions, the training unit enhances problem-solving skills and promotes efficient team coordination. It allows trainees to experience the unique challenges of Hazmat response, such as the proper use of specialized equipment, identification of hazardous substances, and safe containment procedures. The Valve Leak Training Unit is a game-changer in emergency preparedness, enabling agencies to quickly deploy skilled teams ready to tackle complex Hazmat incidents with confidence and precision.

Future Trends in Hazardous Material Training

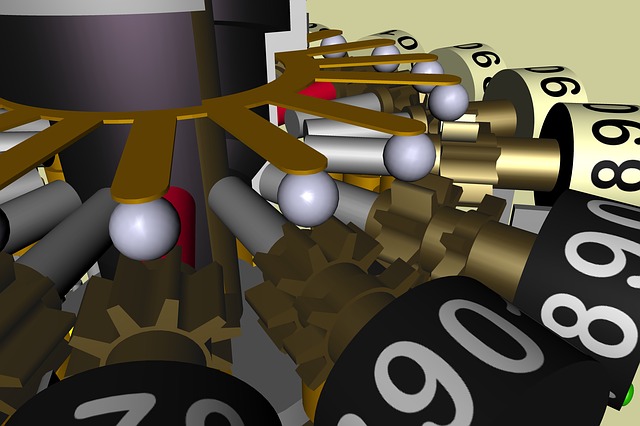

The future of hazardous material (hazmat) training is poised for significant advancements, driven by technological innovations and evolving safety standards. One prominent trend is the integration of immersive simulation technologies, such as advanced virtual reality (VR) and augmented reality (AR) systems, into emergency response training. These tools enable trainees to experience realistic scenarios, including valve leak training units, without the risks associated with live hazardous materials.

Additionally, there’s a growing emphasis on interactive and scenario-based learning, which prepares responders more effectively for unpredictable field conditions. The development of sophisticated simulation platforms allows for customizable training modules, catering to various hazard types and response strategies. This personalized approach ensures that emergency personnel are well-equipped to handle a wide range of hazardous material incidents, enhancing overall safety and efficiency in the process.