In industries dealing with hazardous materials (hazmats), proper handling and emergency preparedness are crucial. Traditional training methods are costly and risky, prompting the development of specialized equipment like emergency offloading training units and hazmat valve simulators. These innovations provide safe, controlled environments for practicing skills like valve operation, product transfer, and leak containment, enhancing operational readiness and safety culture. Key tools include tanker product transfer simulators and valve leak training units, which replicate real-world scenarios, offer versatile practice, and improve preparedness for critical hazmat incidents. Case studies show these advanced training methods lead to faster response times, fewer mistakes, and enhanced hazmat handling capabilities.

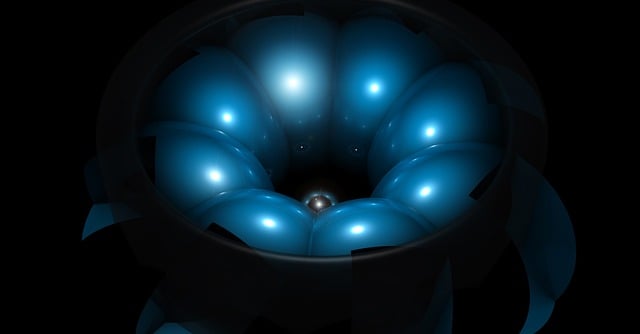

In today’s digital era, efficient and realistic emergency response training is paramount, especially for hazardous material (Hazmat) incidents. The Valve Simulation Tank emerges as a revolutionary tool, offering an immersive hazmat valve training simulator for comprehensive emergency offloading training units. This innovative tanker product transfer simulator enhances skill development with its ability to replicate real-world offloading drill scenarios, including valve leak training units. By incorporating these Hazmat response offloading props, first responders are better equipped to handle critical situations, ensuring swift and safe operations.

- Understanding the Need for Hazmat Training Drills

- Introducing the Valve Simulation Tank: A Revolutionary Training Tool

- Key Features of a Hazardous Material (Hazmat) Valve Training Simulator

- Benefits of Using a Tanker Product Transfer Simulator for Emergency Response Training

- Incorporating Realistic Offloading Drill Props into Your Training Routine

- Case Studies: Successful Implementations of Valve Leak Training Units

Understanding the Need for Hazmat Training Drills

In today’s world, where hazardous material (hazmat) transportation and storage are integral parts of various industries, proper handling and emergency preparedness are non-negotiable. Traditional training methods for hazmat response teams often involve real-world scenarios, which can be costly, logistically challenging, and pose significant risks to trainees and surrounding environments. This is where specialized equipment, such as the emergency offloading training unit, comes into play, revolutionizing hazmat training drills.

These units, incorporating advanced valve simulation technology, offer a safe and controlled environment for practicing critical skills like valve operation, product transfer, and leak containment. For instance, a tanker product transfer simulator enables trainees to experience the intricacies of offloading processes without endangering lives or damaging valuable resources. By using a hazmat valve training simulator or a valve leak training unit, teams can hone their techniques, ensuring swift and efficient response during real-world emergencies. This proactive approach not only enhances operational readiness but also fosters a culture of safety within hazardous material handling operations.

Introducing the Valve Simulation Tank: A Revolutionary Training Tool

Introducing the Valve Simulation Tank: A Revolutionary Training Tool

In today’s digital era, where emergency preparedness is paramount, the need for innovative training solutions has never been more critical. Enter the Valve Simulation Tank—a game-changer in hazmat training drills. This cutting-edge device serves as both an emergency offloading training unit and a tanker product transfer simulator, offering a realistic and controlled environment for practicing high-risk procedures. By replicating the complexities of valve control and leak management, it becomes the ultimate tool for honing skills in hazardous material (hazmat) response teams.

The Valve Simulation Tank provides an immersive experience, allowing trainees to navigate challenging scenarios such as offloading operations and emergency shut-offs without putting themselves or the environment at risk. As a versatile offloading drill training prop and hazmat response offloading prop, it enables efficient practice of various techniques, ensuring teams are well-prepared for real-world situations involving hazardous substances. With its advanced features, this simulator is set to revolutionize how first responders and industry professionals alike approach critical valve leak training.

Key Features of a Hazardous Material (Hazmat) Valve Training Simulator

A Hazardous Material (Hazmat) Valve Training Simulator is an innovative tool designed to revolutionize emergency preparedness and response for hazardous substance management. This advanced training system offers a safe, controlled environment to practice complex valve operations and offloading procedures crucial for hazmat incidents. As a comprehensive emergency offloading training unit, it includes realistic replicas of various valve configurations found in industrial settings, enabling trainees to simulate real-world scenarios without risking exposure to dangerous materials.

The simulator provides an interactive experience with functional valves that can be operated manually or through automated programming, allowing for dynamic training scenarios. This tanker product transfer simulator and offloading drill training prop comes complete with integrated sensors and feedback systems to accurately monitor and assess performance during drills. Its versatile design accommodates different types of hazmat response offloading props, making it a valuable asset for various industries, including transportation, chemical manufacturing, and emergency services. The unit’s durable construction ensures longevity while its customizable features cater to specific training needs, making it an indispensable tool in preparing professionals for effective hazmat response.

Benefits of Using a Tanker Product Transfer Simulator for Emergency Response Training

For emergency responders, the ability to execute efficient and safe hazardous material (hazmat) offloading operations is paramount during critical incident management. A Tanker Product Transfer Simulator offers a cutting-edge solution for this challenge by providing a realistic training environment that replicates the complexities of handling hazardous substances. By employing a hazmat valve training simulator, first responders can hone their skills in controlled scenarios, ensuring they are prepared to handle unexpected situations and potential leaks during real-world emergency response offloading drills.

These simulators serve as invaluable tools for offloading drill training prop, enabling trainees to gain hands-on experience with various tanker product transfer processes. The versatility of a hazmat response offloading prop allows for the simulation of diverse scenarios, from routine transfers to emergency situations, where rapid decision-making and precise valve control are essential. This immersive learning approach enhances the overall effectiveness of emergency response teams, empowering them to confidently and competently manage high-risk situations involving hazardous materials.

Incorporating Realistic Offloading Drill Props into Your Training Routine

Incorporating realistic offloading drill props into your emergency response training is a game-changer for hazmat teams. These specialized pieces of equipment, such as a tanker product transfer simulator or hazmat valve training simulator, allow for immersive and hands-on practice of critical skills like safe and efficient offloading. With these simulators, trainees can experience the nuances of handling various products, learning to navigate through different scenarios and challenges without putting themselves or the environment at risk.

By integrating a valve leak training unit or hazmat response offloading prop, training sessions become dynamic and reflective of real-world emergency situations. This not only enhances the overall preparedness of the team but also ensures that each member is proficient in quickly identifying and addressing potential hazards associated with hazardous material transfers. These realistic props enable teams to rehearse complex procedures, improving their coordination, communication, and confidence during actual hazmat incidents.

Case Studies: Successful Implementations of Valve Leak Training Units

In recent years, organizations across various industries have recognized the importance of comprehensive Hazmat (hazardous materials) training. One innovative tool that has gained significant traction is the valve leak training unit, a specialized simulator designed to replicate real-world emergency offloading scenarios. These units have proven invaluable for preparing personnel to handle potentially catastrophic hazmat valve leaks during tanker product transfer operations.

Case studies from leading chemical plants and refineries demonstrate the effectiveness of incorporating tanker product transfer simulators into their training regimens. By utilizing offloading drill training props that mimic hazardous substances, trainees gain hands-on experience managing leaks while wearing protective gear. This immersive training has led to improved response times, reduced mistakes during actual offloading operations, and ultimately, enhanced hazmat response offloading capabilities. These successful implementations underscore the value of integrating advanced technology into emergency preparedness programs, ensuring that organizations are better equipped to address potential Hazmat incidents with confidence and efficiency.