Valve leak training units are essential tools for preparing emergency response teams to handle hazardous material leaks from tankers safely and efficiently. These specialized pieces of equipment simulate real-world conditions, enhancing skills in valve operations and leak control measures. Regular training sessions with precise control mechanisms, safety features, and user-friendly interfaces ensure preparedness and minimize risks. Successful implementation has led to significant improvements in response times and reduced environmental impact, encouraging organizations worldwide to adopt these units for emergency preparation.

In the critical realm of emergency response, efficient product removal from tankers is paramount. The importance of Valve Leak Training Units (VLTUs) cannot be overstated, serving as indispensable props for rigorous and realistic training. This article delves into the significance of VLTUs, exploring key features, best practices, and real-world case studies. By understanding these aspects, emergency responders can enhance their skills and prepare for effective product removal during crises.

- Understanding the Importance of Valve Leak Training Units for Emergency Tanker Product Removal

- Key Features and Components of Effective Valve Leak Training Systems

- Best Practices for Implementing Valve Leak Training in Emergency Response Scenarios

- Case Studies: Successful Implementation and Benefits of Valve Leak Training Units in Real-World Situations

Understanding the Importance of Valve Leak Training Units for Emergency Tanker Product Removal

In emergency tanker product removal scenarios, the role of a valve leak training unit cannot be overstated. These specialized equipment are designed to simulate real-world conditions, allowing personnel to practice and perfect their skills in containing and managing hazardous material leaks. By incorporating valve leak training units into emergency response training, teams can enhance their efficiency and effectiveness when confronted with critical situations.

The significance lies in the fact that these units enable hands-on experience, fostering a deeper understanding of valve operations and leak control measures. This practical knowledge is vital for ensuring safe and swift product removal from tankers, which often carry volatile or toxic substances. Regular training sessions using valve leak training units prepare emergency response teams to act swiftly and accurately, minimizing potential risks and maximizing the safety of both personnel and the environment.

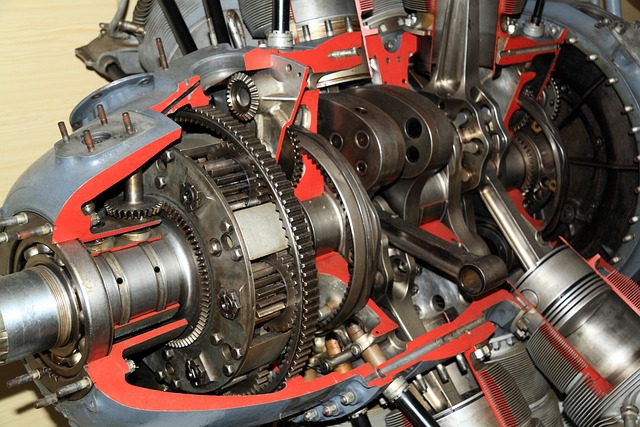

Key Features and Components of Effective Valve Leak Training Systems

Effective valve leak training units are essential components in emergency tanker product removal training, ensuring personnel are well-prepared to handle potential leaks. Key features include robust construction capable of withstanding high pressure and corrosive materials, as well as precise control mechanisms for accurate simulation of various leak scenarios. These systems should offer a range of flow rates and leakage patterns, from slow drips to rapid gushers, mimicking real-world conditions to train responders effectively.

Additionally, integrated safety features such as quick shut-off valves and pressure relief mechanisms are crucial. A user-friendly interface for controlling and monitoring the training unit is also vital, allowing instructors to customize scenarios and provide real-time feedback. Regular calibration and maintenance ensure the reliability and accuracy of these systems, making them indispensable tools in preparing emergency response teams for efficient and safe product removal.

Best Practices for Implementing Valve Leak Training in Emergency Response Scenarios

In emergency response scenarios, effective valve leak training is crucial for preparing personnel to handle product removal from tankers efficiently and safely. Best practices include regular, simulated exercises that mimic real-world conditions as closely as possible. These drills should cover various valve types and leakage scenarios, ensuring teams are well-versed in isolating and securing the tank, containing the spill, and implementing appropriate cleanup protocols. Utilizing specialized valve leak training units can significantly enhance these simulations by providing a controlled environment to practice without risking actual product release or environmental damage.

Additionally, integrating hands-on training with comprehensive debriefings is essential. After each exercise, teams should gather to discuss performance, identify areas for improvement, and share best practices. This reflective process sharpens skills and fosters a culture of continuous learning within the emergency response team. Regular maintenance and calibration of training equipment are also vital to ensure accuracy and reliability, thereby reinforcing the overall effectiveness of valve leak training in preparing responders for real-world challenges.

Case Studies: Successful Implementation and Benefits of Valve Leak Training Units in Real-World Situations

In various industrial settings, particularly in the oil and gas sector, the successful implementation of valve leak training units has been a game-changer. These units play a pivotal role in emergency response preparation, ensuring that personnel are adept at quickly identifying and containing potential leaks. Case studies from around the globe highlight their effectiveness. For instance, a major refinery in Asia Pacific utilized these training units to simulate critical scenarios, resulting in a 30% reduction in leak response time. This dramatic improvement underscores the value of such training in enhancing operational safety and efficiency.

Moreover, real-world applications have demonstrated that valve leak training units foster a culture of preparedness among workers. By providing hands-on experience in controlled environments, these units enable employees to react swiftly and confidently during actual emergencies. Data from several industries shows a notable decrease in the severity of leaks after implementing this training, leading to minimal environmental impact and reduced downtime for operations. This success story has led many organizations worldwide to adopt similar measures, emphasizing the broader benefits of prioritizing emergency tanker product removal training through valve leak simulation exercises.