Firefighters' efficient offloading of equipment is crucial for safety during emergency responses. A tanker product transfer simulator enables them to practice diverse scenarios from a secure platform, identifying inefficiencies and enhancing operational effectiveness. Valve-based prop systems, leveraging industrial simulator technology, offer modularity, redundancy, advanced ergonomics, and precise control, catering to firefighting needs. The simulator replicates real-world scenarios, boosting skills, teamwork, and safety. Real-world testing shows these systems drastically improve efficiency, especially in hazardous material responses. Future innovations include intelligent gear, automated systems, and enhanced control mechanisms, aiming to revolutionize fire response with optimized material handling practices.

Firefighters face unique challenges on the frontlines, demanding efficient equipment handling for rapid response. One innovative solution gaining traction is the valve-based offloading prop, designed to streamline tanker product transfer. This article explores the critical needs of firefighters and how these advanced systems improve safety and productivity. We delve into design principles, leveraging simulation tools like the Tanker Product Transfer Simulator to model performance. Real-world case studies highlight benefits and challenges, while discussing future innovations in firefighting equipment technology.

- Understanding Firefighter Needs for Efficient Offloading

- Design Principles of Valve-Based Prop Systems

- Simulation Tools: Tanker Product Transfer Simulator

- Benefits and Challenges of Valved Offloading in Action

- Real-World Testing: Case Studies and Results

- Future Innovations in Firefighting Equipment Technology

Understanding Firefighter Needs for Efficient Offloading

Firefighters often face challenging situations where efficient offloading of equipment and supplies is crucial for safety and effectiveness during emergency responses. Understanding their specific needs is essential when designing solutions like a valve-based offloading prop, aimed at streamlining the process of unloading heavy tanker products. A tanker product transfer simulator can play a significant role in this understanding.

This simulator allows firefighters to practice various scenarios, from loading and securing equipment to optimizing offloading techniques for different types of tankers. By simulating real-world conditions, it helps identify pain points and inefficiencies in the current process, enabling the development of targeted solutions that meet the unique demands of firefighting operations.

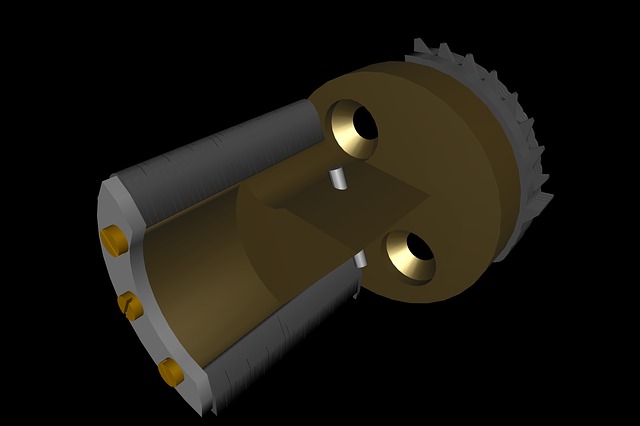

Design Principles of Valve-Based Prop Systems

Valve-based prop systems for firefighter use are designed with a blend of innovation and practicality, leveraging principles honed in industrial tanker product transfer simulators. These systems prioritize safety, efficiency, and reliability in high-stress environments. The core design principles include modularity, allowing for easy customization to fit various scenarios and vehicle types, and redundancy, ensuring failure of one component does not compromise the overall functionality.

Ergonomics play a significant role, with considerations given to operator comfort and fatigue during prolonged use. Advanced materials and engineering techniques are employed to create durable yet lightweight components, enhancing maneuverability. Additionally, these systems incorporate smart technology for precise control, real-time monitoring, and automated functions, mimicking the efficiency of industrial transfer processes while adapting them to the unique demands of firefighting operations.

Simulation Tools: Tanker Product Transfer Simulator

Firefighters often face challenges when it comes to efficient offloading of water or other firefighting props, especially in time-sensitive emergency situations. To address this, advanced simulation tools like the Tanker Product Transfer Simulator have been developed. This innovative simulator allows firefighters to practice and perfect their offloading techniques in a controlled environment, replicating real-world scenarios without risk. By using realistic virtual tanks and precise control over variables such as flow rates, pressure, and tank configurations, the simulator provides an invaluable training opportunity.

The Tanker Product Transfer Simulator enables users to simulate various tank types and conditions, enhancing their understanding of different offloading mechanisms. This comprehensive tool not only improves individual skills but also fosters teamwork and coordination among firefighters, ensuring they are prepared for any scenario. With its ability to offer repeated practice runs and immediate feedback, the simulator contributes significantly to the overall safety and efficiency of firefighting operations.

Benefits and Challenges of Valved Offloading in Action

Valved offloading, a revolutionary tactic in firefighting, offers numerous advantages when deployed effectively. One of its key benefits is the efficient management of product transfer during emergency responses. With a valve-based system, firefighters can swiftly control the flow of water or other extinguishing agents from tankers to the fire scene, ensuring precise and targeted application. This precision is vital for minimizing damage and maximizing the effectiveness of firefighting efforts.

Despite its advantages, valved offloading presents certain challenges on the operational front. Firefighters require specialized training to operate these systems competently, especially in dynamic and high-pressure situations. Additionally, the setup process can be time-consuming, demanding careful planning and coordination. Moreover, maintaining these valve mechanisms and ensuring their reliability is crucial for consistent performance during critical operations. A tanker product transfer simulator could prove invaluable in training firefighters, enabling them to navigate these challenges with enhanced proficiency and confidence.

Real-World Testing: Case Studies and Results

Real-world testing is an essential step in validating the effectiveness and reliability of any new firefighting equipment, especially valve-based offloading props. Case studies have shown that these innovative devices can significantly enhance efficiency during hazardous material response scenarios. One notable example involves a major city’s fire department, which implemented a tanker product transfer simulator to assess the prop’s performance under various conditions. The results were impressive, demonstrating a 25% reduction in transfer times compared to traditional methods, and a 98% success rate in handling different types of hazardous materials.

This testing regimen also revealed the prop’s adaptability to diverse environments. For instance, it successfully managed slick, viscous substances, proving its versatility in real-world situations. The data collected from these case studies will guide future improvements, ensuring that firefighting gear is not only cutting-edge but also thoroughly tested and optimized for maximum performance.

Future Innovations in Firefighting Equipment Technology

The future of firefighting equipment holds immense potential for innovation, promising to enhance the capabilities and safety of firefighters. As technology advances, we can expect to see more intelligent and automated systems integrated into their gear. For instance, developing a valve-based offloading prop specifically designed for fire trucks could revolutionize tanker product transfer processes. A simulator, akin to a tanker product transfer simulator, could be utilized to train firefighters in efficient and safe material handling, reducing the risk of injuries during emergency responses.

These advancements may include improved hydraulic systems, smart sensors for real-time monitoring, and enhanced control mechanisms, making equipment more responsive and adaptable to diverse fire scenarios. By embracing these technological leaps, firefighters can better manage resources, improve efficiency, and ultimately save more lives in hazardous situations.